Two interesting prints today from my Printrbot Jr.

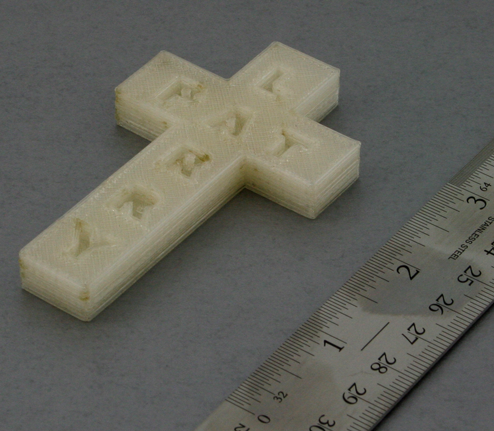

The first for the inlaws:

I’m lucky that their names intersect well! For some reason, I got globs of burnt looking plastic here and there. Maybe the nozzle temperature was too high (I’m running PLA at 205c to try to prevent extruder jams).

This one was surprisingly hard to create — I didn’t realize at first that Blender cubes (which is what this is made out of) end up being hollow when they print. Slic3r kept complaining about the model. Eventually i just created a 2D cross and extruded it; I have to go back and figure out how to print solid Blender mesh cubes 🙁

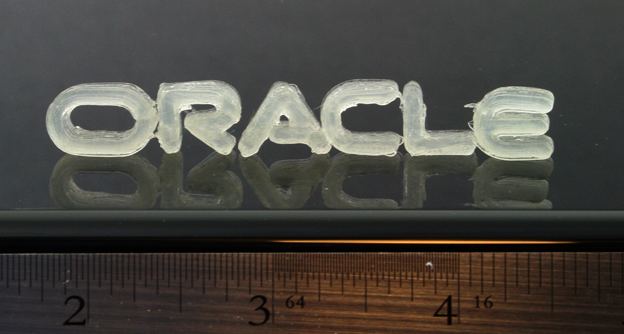

The second print was the logo of the company I work for, done in miniature:

I already had the logo in 3D in Blender for graphics work, and so I just printed it. I think that if I print the logo a bit larger it will look better: this is pushing the resolution of the printer. technically, this is about 20 point type — you can see how a 3D printer has much lower resolution than a modern ink jet! (to be fair, though, the 3D printer prints one dot at a time, so to speak).